Roof kits for shipping containers have become increasingly popular as an efficient and cost-effective solution for various industries. As a versatile option, these roofing systems can be utilized by both DIY enthusiasts and professionals alike, providing the necessary structural integrity to protect valuable assets stored within the container.

In this comprehensive guide, we will explore top-rated roof kits brands such as Shield Roof Solutions and Mobile Modular Portable Storage that offer exceptional durability and easy conversion processes. We’ll delve into essential features of a high-quality shipping container roof like double truss construction with galvanized steel Q215, waterproofing capabilities, and fire resistance with a B1 conductive rating.

Furthermore, we will discuss size considerations and structural planning tips when incorporating these innovative roof kits for shipping containers in your projects. This includes consulting structural engineers for large-scale endeavors or considering snow load capacity in colder climates. Additionally, you’ll gain insight into installation processes, and equipment requirements as well as material selection & design options available on the market today.

Table of Contents:

- Roof Kits for Shipping Containers Overview

- Benefits of Using Roof Kits for Shipping Containers

- Top Companies Offering High-Quality Roofing Solutions

- Creating a Container Garage with Roof Kits

- Considerations for Large-Scale Projects Involving Heavy Loads

- Installation Process and Equipment Requirements

- Selecting Suitable Materials Based on Local Weather Conditions

- Attaching Container Roof Internally or Externally

- Applications Beyond Storage Facilities

- FAQs in Relation to Roof Kits for Shipping Containers

- Conclusion

Roof Kits for Shipping Containers Overview

Roof kits for shipping containers are an economical and versatile solution for various applications, catering to both DIY enthusiasts and professional contractors. Companies like Shield Roof Solutions offer 20-year guaranteed roofing kits made from American steel, ensuring durability and quality.

Benefits of Using Roof Kits for Shipping Containers

- Economical: Container roof is a cost-effective alternative to traditional construction methods while maintaining the integrity of the structure.

- Versatile: These roof kits can be used in numerous applications such as garages, workshops, storage facilities, or even living spaces when combined with appropriate insulation materials.

- Durable: Made from high-quality galvanized steel, these roofs provide excellent protection against harsh weather conditions and corrosion over time.

- Simplified Installation Process: Pre-fabricated designs allow for easy assembly by either the customer or a professional contractor if preferred.

Top Companies Offering High-Quality Roofing Solutions

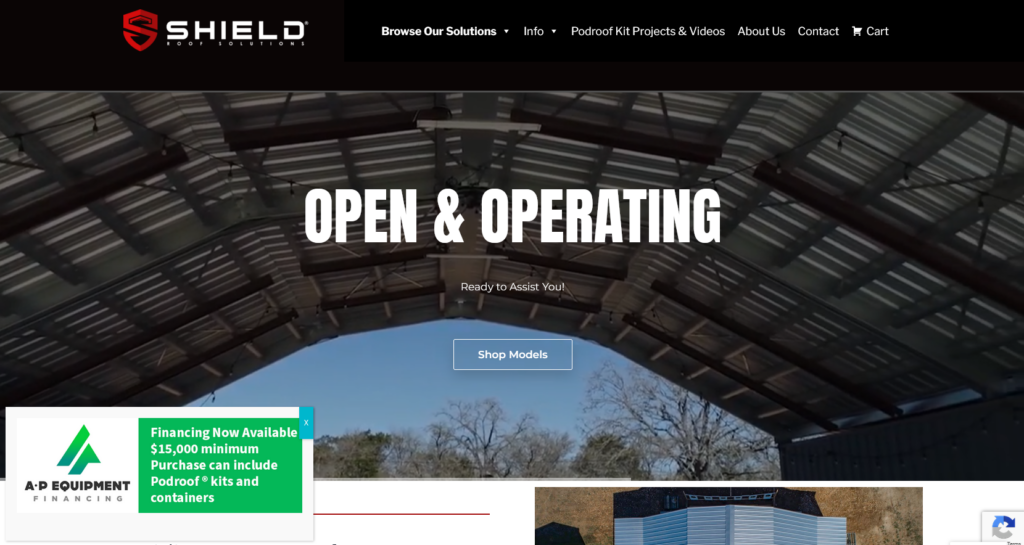

- Shield Roof Solutions: This company specializes in providing durable roof kits for container options that come with a 20-year guarantee on their American-made products. Their range includes single slope covers as well as gable-style structures suitable for different project requirements.

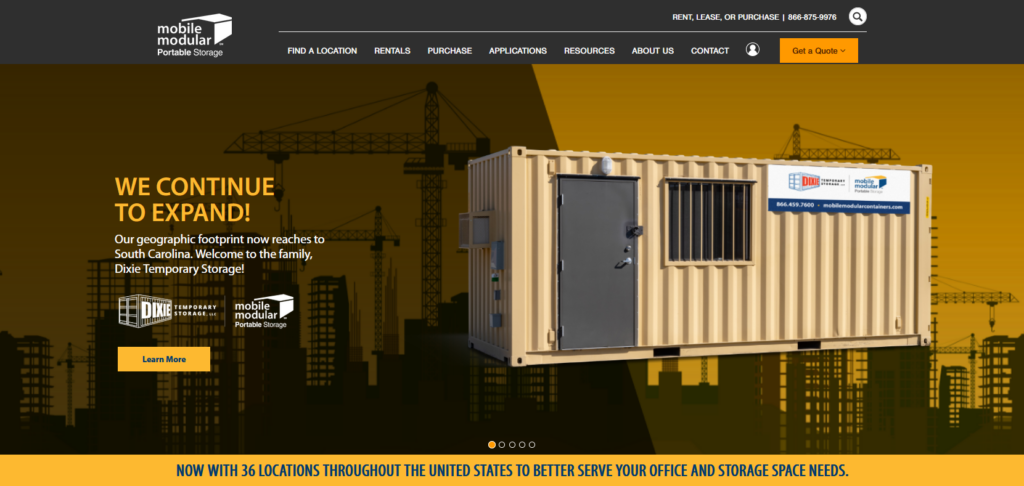

- Mobile Modular Portable Storage: A leading provider of portable storage containers also offers innovative steel cover systems designed specifically for use atop their units. With multiple sizes available depending on your needs, these kits can be easily installed to create functional workspaces or secure storage areas.

Note: When using these roof kits, it is important to ensure that the container’s roof is structurally sound and able to support the weight of the new roof. It is recommended to consult with a professional contractor to assess the integrity of the container roof structure before installation.

Roof kits for shipping containers can be a cost-efficient means of improving the worth and security of your property. With the right tools and instructions, you can easily create a secure garage with these durable kits. Now let’s look at how you can take advantage of this versatile solution by creating your own container garage with roof kits.

Creating a Container Garage with Roof Kits

One common application of roof kits for containers is creating a container garage by installing a roof between two containers. Steel covers are strong, durable, and can be permanent if required. Companies like Mobile Modular Portable Storage offer storage containers that can be easily converted into functional workspaces or secure storage areas with the addition of these innovative steel cover kits.

Advantages of Converting Containers into Garages

- Economical: Utilizing containers for garages is cost-effective compared to traditional construction methods.

- Versatile: These structures can serve multiple purposes such as workshops, equipment storage, or even living spaces when properly insulated.

- Durable: Made from high-quality materials like galvanized steel, container roofs provide excellent protection against harsh weather conditions and maintain their structural integrity over time.

- Sustainable: Repurposing used containers reduces waste and promotes eco-friendly building practices.

Steps to Create Your Own Container Garage

- Select two suitable containers: Ensure they’re in good condition and have similar dimensions for proper alignment during installation.

- Purchase an appropriate roofing kit: Choose one based on your desired width coverage, roof kits for a container, shipping container roof, shipping container, a shipping container, container’s roof, the integrity of the structure, and local weather conditions.

- Prepare the site: Level the ground, create a solid foundation for your containers, and ensure proper drainage to prevent water accumulation.

- Position the containers: Place them parallel to each other with enough space in between for your desired roof coverage.

- Install the roof kit: Attach the container roof following the manufacturer’s instructions and secure it with bolts or welding as needed.

Creating a container garage with roof kits is an easy and cost-effective way to add more storage space. With the right roof kits for shipping containers, you can create your own customized garage in no time. Examining some of the top-rated container roofs available, let’s delve into what options are out there.

Top-Rated Roof Kits for Shipping Containers on the Market

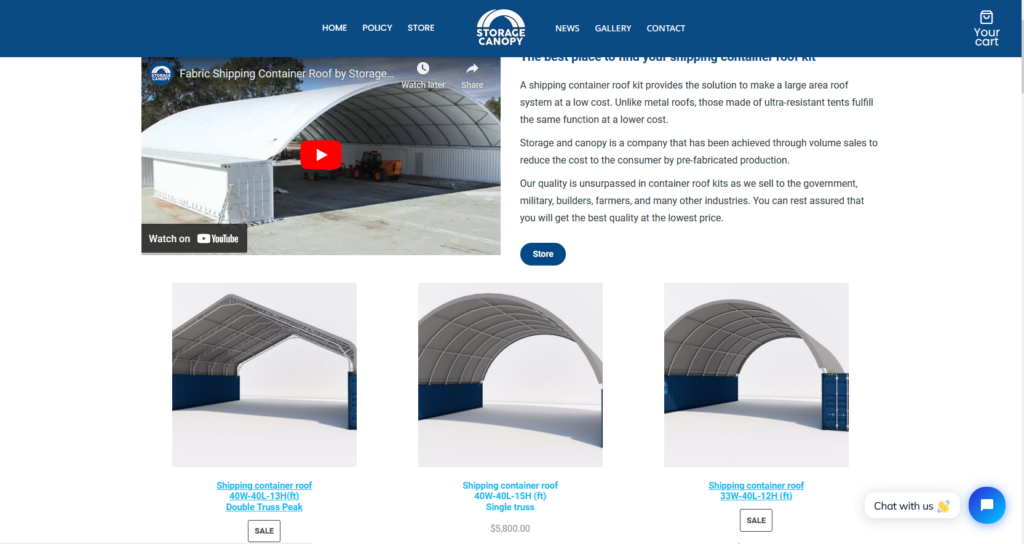

The top-rated roof kits for shipping containers on the market is the Storage and Canopy Container Roof, which features double truss construction made from galvanized steel Q215. This type of shelter is waterproof, and fire-resistant due to its B1 conductive rating, and has a coated steel roof cover that’s seven times more resistant to corrosion than regular galvanized steel.

Features of Storage & Canopy Container Roofs

- Durability: Made with high-quality materials like galvanized steel Q215 for long-lasting performance.

- Weather Resistance: Waterproof design protects your belongings from rain, snow, and other harsh weather conditions.

- Fire Resistance: Boasts a B1 conductive rating for added safety in case of fire hazards.

- Aesthetic Appeal: The sleek design adds an attractive touch to any container setup while providing functional protection against various elements.

Comparing Different Types of Roofs Available in the Market

In addition to Storage & Canopy’s offering, there are several other types of container roofs available in the market. Some popular options include single-slope designs by companies like Western Shelter Systems or flat-top models offered by Shield Roof Solutions.

It’s essential to assess the options based on criteria such as cost, robustness, installation simplicity and customizability prior to making a final selection. For example:

- If you’re looking for a budget-friendly option without compromising quality or performance, consider Western Shelter Systems.

- For those who prioritize customization and a variety of design options, check out the range of products offered by Shield Roof Solutions.

Ultimately, selecting the best shipping container roof kit for your needs will depend on various factors such as budget constraints, intended use, and local weather conditions.

The premier roof kits for shipping containers available provide optimal shielding from extreme weather, making it a great selection for major projects. Now let’s take a look at considerations for heavy loads and how structural engineers can help strengthen roofs in cold climates.

Considerations for Large-Scale Projects Involving Heavy Loads

When planning large-scale projects involving heavy loads, such as gardens or decks atop flat-roofed containers, it’s essential to consult with structural engineers. These professionals can help ensure the integrity of the structure of your container roof and provide guidance on necessary reinforcements. This is particularly important in colder climates where snow load capacity should be considered.

Importance of Consulting Structural Engineers

- Safety: A structural engineer will assess the weight-bearing capacity of your container’s roof, ensuring that it can safely support additional loads without compromising its stability.

- Compliance: Working with a professional ensures adherence to local building codes and regulations, avoiding potential fines or penalties down the line.

- Economical design solutions: An experienced engineer can recommend cost-effective reinforcement options tailored to your specific project requirements.

Strengthening Measures for Cold Climates

In regions prone to heavy snowfall, additional strengthening measures may need to be implemented using columns or beams. Some possible solutions include:

- Portal frames: these are rigid structures made from steel that distribute vertical loads evenly across their length.

- Tapered plate girders: These are beams with varying depths, providing additional support where it’s needed most.

- Steel trusses: These consist of triangular units that distribute weight more evenly than traditional beams or columns.

Taking these factors into account will help ensure the success and longevity of your roof kits for shipping containers project. When searching for roof kits for shipping containers, it’s important to keep in mind the importance of consulting with structural engineers and reinforcing the roof as necessary to ensure safety and the integrity of the structure.

A structural engineer’s consultation is imperative for any endeavor involving hefty loads, so that the stability and security of the construction can be guaranteed. Moving on, installation process and equipment requirements should be taken into consideration when planning for such a project.

Installation Process and Equipment Requirements

Installing pre-fabricated container roofs is designed to be simple for customers who wish to save money on installation costs. However, professional assistance may still prove beneficial for first-time buyers. Kits typically ship within two working days after purchase but require access to equipment like forklifts during unloading at delivery sites unless otherwise arranged beforehand at an additional cost.

DIY vs. Professional Installation

If you’re a DIY enthusiast with some experience in construction, installing roof kits for shipping containers can be manageable. However, if you lack the necessary skills or tools, it’s recommended that you hire a professional contractor familiar with shipping containers and their integrity of the structure. A knowledgeable installer will ensure your project meets safety standards and lasts longer.

Necessary Equipment and Tools

- Forklift: To unload the roof kit from the delivery truck.

- Ladder: For accessing the top of the shipping containers during installation.

- Safety harnesses: To protect workers while they install the roofing system atop containers.

- Bolts or welding equipment: Depending on whether you choose bolting or welding as your attachment method (discussed further in Heading 7).

- Tape measure & level: To ensure proper alignment of components during the assembly process.

Remember, investing in high-quality materials such as galvanized steel Q215 used by Storage & Canopy Container Roofs ensures your project’s durability and longevity. To get the most out of your roof kits for shipping containers, consider hiring a professional contractor if you’re unsure about tackling the installation yourself.

It is essential to consider the installation process and equipment requirements when installing roof kits for shipping containers. Selecting materials that are appropriate for the local climate can be critical in ensuring your roof’s longevity.

Selecting Suitable Materials Based on Local Weather Conditions

When selecting suitable materials for your roof kits for shipping containers, it’s crucial to consider factors such as local weather conditions. For example, in states experiencing intense snowfall, opting for double-truss designs can provide better support and durability. Additionally, the choice of material should take into account fire resistance and overall longevity.

Factors Affecting Material Selection

- Snow Load Capacity: In colder climates with heavy snowfall, choose a design that can withstand the additional weight without compromising the integrity of the structure.

- Fire Resistance: Ensure the chosen material has an appropriate fire-resistant rating like B1 conductive rating found in Storage & Canopy Container Roofs (source). This will help prevent potential damage or loss due to fires.

- Durability: Opt for materials that are resistant to corrosion and wear-and-tear over time. Galvanized steel is commonly used in container roofs because of its long-lasting properties.

Different Types of Fabric Covers

The structure of these roof kits is generally made from galvanized steel; however, fabric covers are also available depending on your requirements. Fabric cover options include:

- 450g PVC (Polyvinyl Chloride): A lightweight option ideal for smaller-sized projects where less coverage area is needed.

- 900g PVC: A heavier and more durable option suitable for larger-sized projects that require greater coverage area.

When selecting a fabric cover, consider factors such as UV resistance, water resistance, and the ability to withstand harsh weather conditions. This will ensure your roof kits for shipping containers remains functional and aesthetically pleasing over time.

Taking into account the climate of a particular area is essential when selecting materials for roofing a container in order to ensure its durability. Attaching roofs internally or externally requires careful consideration and understanding of the pros and cons associated with each method in order to make an informed decision.

Attaching Shipping Container Roofs Internally or Externally

Container roofs can be attached to either the inside edges or outside edges of two containers depending on your preference. However, it’s important to note that attaching them internally will result in a loss of width space within the containers themselves. For temporary solutions, bolting may suffice; however, welding provides more support if you require a permanent installation.

Pros and Cons of Internal vs External Attachment Methods

- Internal attachment: Attaching the roof kits for shipping containers internally offers better protection from wind and rain but reduces available interior space. This method is suitable for projects where weatherproofing is essential, such as storage facilities or workshops.

- External attachment: Opting for external attachment maximizes internal space but might expose the structure to harsher weather conditions. It’s ideal for applications like garages or living spaces where maximizing usable area is crucial.

Bolting vs Welding Considerations

The choice between bolting and welding when attaching a container roof depends on factors like permanence, the integrity of the structure, and ease of assembly. Here are some key points to consider:

- Bolting: This method allows for easier disassembly if needed in future relocations or modifications since bolts can be removed without damaging the container’s structure. Bolts also offer sufficient strength in most cases; however, they might not provide enough support under extreme loads or high winds.

- Welding: If you’re looking for a more permanent solution, welding offers superior structural integrity and strength compared to bolting. It’s important to hire a professional welder if you choose this method since improper welding can compromise the container’s roof structure.

Ultimately, the choice between internal or external attachment methods and bolting vs welding depends on your project requirements and preferences. Be sure to consult with professionals like Myrooff when planning your shipping container roofing project for expert advice tailored to your specific needs.

Attaching container roofs internally or externally is a complex process that requires careful consideration of the pros and cons of each method. With applications beyond storage facilities, such as industrial uses and creating living spaces with shipping container roofs, it is important to consider all aspects before beginning construction.

Key Takeaway:

When attaching roof kits for shipping containers, you can choose between internal or external attachment methods. Internal attachment offers better protection from wind and rain but reduces available interior space, while external attachment maximizes internal space but might expose the structure to harsher weather conditions. The choice between bolting and welding depends on factors like permanence, structural integrity, and ease of assembly.

Applications Beyond Storage Facilities

Container cover buildings have numerous applications including industrial, commercial, and construction projects such as workshops, storage facilities, or even living spaces when combined with appropriate insulation materials like aluminum foil and bitumen. With widths ranging from 20 feet up to 50 feet (or potentially larger in specific locations), there’s plenty of scope for customization according to individual needs.

Industrial Uses

Container roofs are not limited to residential garages; they can also be used in various industrial settings. For instance, these structures provide excellent protection for equipment and machinery on construction sites or serve as temporary warehouses during large-scale events. Additionally, container roof kits can be utilized for creating covered workspaces that shield employees from harsh weather conditions while still allowing natural light into the area.

Creating Living Spaces with Shipping Container Roofs

Innovative architects and designers have been exploring the potential of a container as sustainable building blocks for modern homes. By adding a high-quality roof kit atop two parallel containers, it is possible to create an open-concept living space that offers ample room for daily activities while maintaining the integrity of the structure.

- The addition of windows and doors transforms these steel boxes into cozy dwellings complete with natural light.

- To ensure comfort year-round, proper insulation is essential – consider using spray foam insulation or installing insulated panels within the walls.

- Eco-friendly enthusiasts may opt for green roofing systems by incorporating vegetation on top of their container’s roof, which helps regulate temperature and promotes biodiversity.

Overall, roof kits for shipping containers provide a versatile solution for various applications beyond storage facilities, proving their worth in both industrial settings and as innovative living spaces.

FAQs in Relation to Roof Kits for Shipping Containers

How to Waterproof the Container Roof

To waterproof a shipping container roof, you can apply an elastomeric coating or use specialized rubber gaskets. The elastomeric coating forms a seamless and flexible membrane on the surface, preventing water infiltration. Rubber gaskets can be installed between overlapping panels to create watertight seals.

Can You Put a Roof on a Container?

Yes, you can install various types of roofs on a container for added protection and aesthetics. Roof kits designed specifically for containers are available in different materials such as galvanized steel structures or fabric covers (450g PVC or 900g PVC). These kits provide easy installation options like bolting or welding.

How Much Weight Can You Put on a Shipping Container Roof?

A standard ISO container’s corner posts support most of its weight; however, the roof load capacity varies depending on factors like material type and structural design. Typically, it is advised not to exceed 300 kg (660 lbs) per square meter when placing loads directly onto the flat panel areas of the roof.

What Is the Roof of a Container Made Of?

The majority of container roofs are made from corrugated Corten steel sheets that offer strength and durability while resisting corrosion. This weathering steel alloy provides excellent long-term performance with minimal maintenance requirements.

At Myrooff, we offer high-quality roof kits for shipping containers that are designed to provide integrity for the structure of the container roof and protection for your container’s roof. Our kits are easy to install and come in different materials to suit your needs. Contact us today to learn more about our shipping container roofs and how we can help you.

Roof Kits for Shipping Containers – A Recap

In conclusion, roof kits for shipping containers are an economical and practical solution for various industries. They are suitable for both DIY enthusiasts and professionals alike, with high-quality features such as double-truss construction, waterproofing capabilities, and fire resistance.

When considering container cover buildings, it’s important to consult structural engineers for large-scale projects and consider snow load capacity in colder climates. The simplified installation process requires specific equipment requirements and shipping time. Material selection includes galvanized steel structures with fabric cover options (450g PVC or 900g PVC), while attachment methods include internal vs external attachment methods with bolting versus welding options.

If you’re interested in learning more about shipping container roof kits or other roofing solutions, visit myrooff.com today!