A hip truss roof is a kind of roof whose slides come with a gentle slope and it tends to slope down toward the walls. Hip roofs require an extremely complicated system of trusses and rafters. This kind of roof doesn’t have any vertical slides or gables. Though in present days this kind of roof is mostly seen in cottages and bungalows, the hip roof style is widely being used in a vast range of architectural structures.

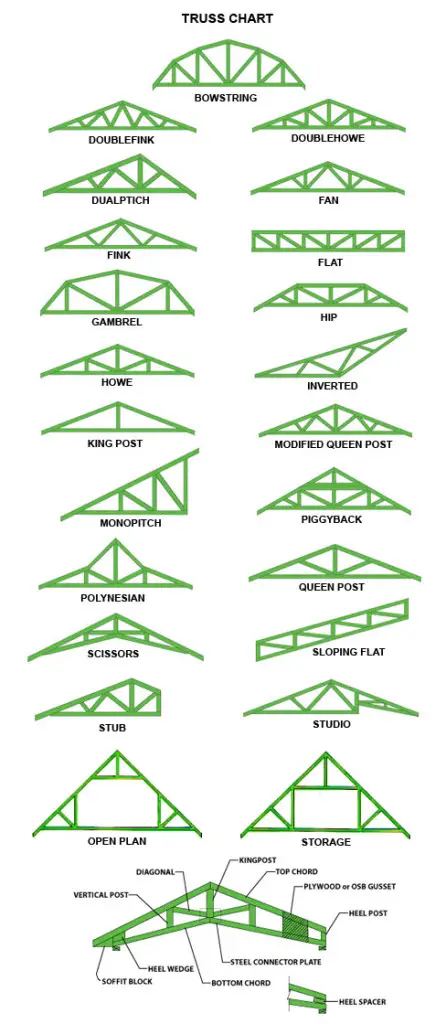

In order to fully comprehend the hip roof truss system we have to take a closer look at the different kinds of trusses used in the hip roof.

Truncated Standard Truss: this has the shape of a standard truss, but its top portion is cut off so that the slope fits on the top of the hip end.

Truncated girder truss: The main truss which lies on the hip end is known as the truncated girder truss. It carries the weight of the outer hip trusses along with that of the creeper trusses, jack and hip. Therefore, this is the strongest of the truncated trusses since it has to take all the loads.

Hip truss: Hip truss is responsible for forming the hip line on the roof. Though not much different from the half truss, the hip truss comes with an elongated top chord which finishes as the hip top.

Jack truss: The jack truss runs right into the hip truss. Just like the hip truss, it has an extended top chord which meets the hip truss.

Creeper truss: this is the truss which meets the hip truss without any elongation of the top chord.

Scissor Truss: This is a modified truss created to suit a ceiling with slopes. They come with an equal pitch ceiling on either side of the apex.

Bell truss: This truss is most commonly seen on Federation houses. The top chord comes with 2 different pitches and the lower pitch covers the patio or balcony.

Bowstring truss: They are mainly used for commercial building where the top chords are designed so as to make way for a curved roof.

Cantilever truss: This could be any other truss provided that the support point is located within the span and not at the heel.

Cut off truss: They can be any variety of trusses, but they don’t come with a heel.

Half truss: this is a full truss which has been cut off from the apex.

Framing the hip roof:

Now that we know the names of all the various kinds of hip roof trusses let us move on to the more important aspect of our article, viz. hip roof truss plans.

Hip roof truss framing isn’t a very easy job, but if you have the right tools and proper guidance framing a hip roof can be a simple task.

Similar to a gabled roof, a hip roof is also made out of common rafters along with jack rafters and hip rafters. Framing the hip roof can be more expensive than framing a gabled roof since you need to pay for the labor cost for framing the hips.

It not only leads to a chicer look, but also makes the building more resistant to wind.

HIP ROOF TRUSS LAYOUT

The initial step in framing this roof is not much different from that of the gabled roof. This step involves finding the run of a common rafter. This would enable the builder to place the joists of the ceiling by the side of the hip jack and common rafters.

For instance, let us suppose we have to frame a hip roof for a building measuring 12’x28’. During this stage we are going to concern ourselves not with the pitch of the roof, but rather with the run of the common rafters.

So, we have to start by measuring the exact width of the building so as to find the run of the common rafter.

Therefore, we will be using 12’ rafters in this case. Make use of a construction master calculator and enter 12 feet. Now deduct the thickness of ridge board divided by 2.

This would be about 5 feet and 11 ¼ inches run of the common rafter. Now that you know the run of the common rafters you need to measure the outside corners of the house where the hips are to be placed.

Once you have laid out the common rafters, you would need to place the ceiling joists alongside the area where the rafters would be placed. One can choose to leave the ceiling joist ends out till the hip rafters are located.

Construction of the hip roof:

The first thing you need to do is set up the ridge board. Once you have set up the ridge board you will get to know the location of the hips.

You will need a minimum of 3 carpenters to set this board on the roof. Moreover, you need 6 common rafters properly cut and located close to their final destination.

While 2 of the carpenters needs to be located in the middle of the building close to the area where the board ends, the third carpenter needs to hand over the commons to the carpenters in the middle.

Now you can start by fixing one rafter on the top of the wall right next to the joist of the ceiling. The carpenter in the middle must help you hold the top in its desired location.

Now, go to the opposite side of the house and do the same thing. The carpenter working in the middle needs to allow the plumb cuts to rest together and support the load.

This process also needs to be repeated with the 3rd carpenter on the opposite side of the ridge board.

The carpenter working outside of the wall needs to pass the ridge board on to the others working in the middle. He can also help them with slipping the ridge between the commons and nail them together.

The king common rafters can now be placed on the ends of the ridge board so as to fix the ridge in its final location. Now you can start with setting the hip rafters.

This job generally can be done by 2 carpenters, but again that depends on the size of the building. Always start by nailing the bottom first. At this time, you can set the remaining commons so as to give a head start on the hip jacks.

Hip Jack Rafters:

Straighten the hip jack with a string line and a temporary brace before setting up the jack rafters.

The jack rafters need to be nailed on the opposite side of the hip rafter so as to keep it erect. The last step consists of installing the fascia before you apply the sheath.

Prefabricated Hip roof trusses

However, if you want to avoid all these complications you should just go for the premade hip roof trusses.

Most new homes in the USA make use of manufactured roof trusses for framing. They are meant to replace the ceiling joists and rafters which are required for traditional framing.

This not only leads to greater speed and accuracy, but also helps you save on your expenditures. Any modern builder would advise you to go for prefabricated hip roof trusses since they are so much easier to erect and result in much lower expenses.

Advantages of prefabricated hip roof trusses:

Firstly, premade hip roof trusses span a longer distance and can do without the presence of inside weight bearing walls.

Secondly, prefabricated hip roof trusses are much less expensive than stick roof framing since they come in short lengths of 2/4 stock. This is different from the huge framing members used for conventional framing of the ceilings and rafters.

Prefabricated trusses can be easily designed to suit all kinds of ceiling or roofs used in most modern homes.

The prefabricated hip roof trusses are created and designed by engineers so that they can meet the load of the roof along with the requirements of the building code.

The premade hip roof trusses can easily be erected in one day. This leads to reduced expenditure and of course much less hassles.

Lastly, even novices can be used to erect these trusses, thus further reducing your cost of labour.

Advantages of the hip roof:

- The consistent fascia on all the sides ensures that one can install gutters all around the building.

- They are suitable for hot tropical weather since they provide shade on all the sides.

- Since all the 4 sides of the roof are angled it leads to better drainage and eliminates all possibility of standing water on the roof.

- The aerodynamic design of this kind of roof makes it ideal for windy and storm prone locations.