Roof Truss Design – Material for the roof should be selected after determining the purpose of the structure. The stress value of any structure should not exceed the permissible limit, as it can lead to collapse of the whole structure.

This is because the pitch of a roof depends solely on the roof truss. With the ever increasing demand to optimize the land, the builders are looking towards such type of roof trusses which provide a solution to every requirement.

The traditional way to build the roof was on site where the carpenter used to fix the wall plates and ridge plates to make the structure and then cut the rafters to the required length.

It all happened on the site and though it was the acceptable way, yet it was quite complex as it included human measurements.

Currently, prefabricated roof trusses have replaced the skill of roof carpentry. Now the trusses are just lifted and craned quite easily and quickly.

Trusses can be customized according to the requirement and thus serve as a simplified way of roofing. Steel roof truss design example is evident in the major structures built across the globe.

Steel trusses are mainly used to build the strong base. They are being used for both buildings and bridges. Design of roof truss should follow the general layout that is prepared first. After that, the external load is to be estimated including the self-load of the truss.

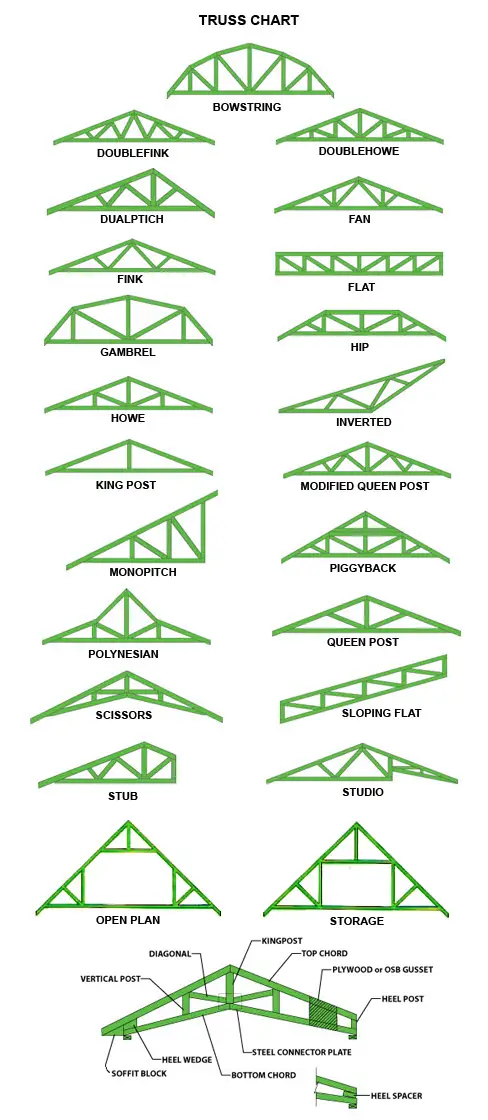

Different steel roof truss designs are prepared depending upon the shape of the structure. There are parallel and triangular, and trapezoidal trusses. Parallel trusses are used for deep roofs, whereas triangular are usually employed in the trusses with steep pitches.

It can be said in the case of steel roof truss design calculations that the cost of truss should be equal to twice the cost of purlins and the cost incurred on the roof covering. Purlins are used for small roofs which are covered with steel roofing.

Purlins are light and therefore easily fit between the steel structures and are quite economic. Gravity load also plays a very important role in determining the strength of the structure.

If the gravity load of the building exceeds the net uplift load, which generally happens in the case of roof buildings, the compression within the loads should be high to manage the slope.

Shed roof truss design consists of two rafters which hold up the roof of the structure and give it the desired shape. The number of trusses required for shed roof truss depends upon the length of the roof. Generally, the roofs that are wide and longer require more trusses to cover up.

The trusses are simple to construct and install. It is easy to make this roof truss with the help of wood. The number of rafters required to build the trusses are generally double the number of roof trusses required depending upon the length of the roof.

They are prepared in triangular form so as to cover all the joints between the rafters and the other parts at the surface. The trusses can be set in place using glue and nails.

Flat roof truss design is used in intermediate flat structures because its spans are not of a much higher range.

They are used in construction of roofs of fairly large objects such as shopping malls, logistical parks and warehouses. These structures generally have a flat roof structure because they are already at a high height.

Warehouses are installed with this type of truss because they are to be fitted with different amenities. A flat roof structure does not let the heat enter and the coldness escapes. This way it balances the inner temperature.

There are different flat trusses depending upon the thickness, width and layout of the internal webbing. It depends upon the selected truss span; roof slope and the roof load that which kind of truss shall be suitable.

Attic truss roof design is intended to provide a solution for additional living area within the roof space.

The attic truss is able to support more load than a standard truss of the same span and pitch. In this type of truss roof a high collar beam and two struts make a wide and open expanded area which forms a wide livable space.

They are designed in such a manner which clears the span between the front and rear walls of a dwelling.

Therefore, even when the attic area is being covered with trusses it does not require additional load bearing on walls and avoids the need of a deep foundation on a lower story.

This means that they can be installed in an already built building without affecting the strength and longevity of the structure. It provides the structural roof and the additional floor in the less used area.

An attic roof is a wise option if you need additional space at your place. The units of attic trusses are assembled and thus can be fitted easily. It also acts as a weather tight shell which can be erected quickly as the structures are readymade and save a lot of labor cost.

This innovative structure provides independence to plan the room layout as required and dreamt of. The plaster board and the floor boarding also form part of an attic roof.

Roof trusses design plans are prepared to make sure that the design of the roof truss suits the building after taking into account the loading pressure on roof, truss spacing required and the materials used in roofing.

The shape of the roof, span of the truss and loads play a significant role in choosing the type of roof truss to be used. Along with this the safety factors are also to be evaluated.

There is a requirement of an appropriate medium which can assist in the roof truss design as designing is the foundation of any truss. The following factors shall act as a roof trusses design Guide which must be considered prior to all other factors.

The load of the roof is measured in kilonewtons per square meter. The dead load and snow load of the building are accumulated to calculate the overall load of the roof. Spacing of the roof should be adjusted to meet the load.

The roof which is below an adjacent higher roof or the l and T shaped buildings has higher chances on unusual snow loads. The truss spacing should be reduced on such spaces so as to maintain the strength and stability of the roof.

The ungraded lumber can harm the safety of the roof. The lumber should be thick enough so that there can be established a strong connection between the surface of the trust and the nails used for affixing.

The top and bottom truss members should be fitted with the best quality lumber as lumber adds an advantage to the roof.

To manage the spans and spacing sometimes the top and bottom chords are to be spliced. The lowest bending stress of the top chord is spliced generally and the mid-span is spliced for bottom chord as forces are smaller at mid-span.

It is to be ensured that the lower chord splice is not located directly below the ridge ventilation slot as at this spot the wetting due to rain followed by condensation can corrode the steel or the other material used.

Trusses are labor intensive and require connection devices therefore they are to be manufactured and install in a manner which provides considerable economies of scale. The following factors can elaborate how to design roof trusses and what factors are to be considered while designing them.

- ROOF STRUCTURE: While determining that the truss roof will be the best choice for the roof it is essential to match the compatibility of the roof type with the truss. Truss does not support all kinds of roofs. Trusses are highly suitable for the roof types which are flat, saddle or single pitch. It is averagely suitable for a hipped roof as well. But it is not very compatible for pyramid roofs.

- PRESSURE ANALYSIS: The upper chord and the lower chord are under compression and tension. This state depends upon the inclination of the diagonals. It is required to manage the pressure on the roof by analyzing as extreme loading can change the sign of structure which will result in making the upper chord be under tension and the lower be under compression.

- BUCKLING OF MEMBERS: The strength and stability are termed as members of the truss. Steel can handle the tensile forces in roof truss, but the compression members are to be taken well care of. Composite and stiffened compression members must be used so as to save them from buckling down.

- MANAGING THE SYSTEM LINES: The system lines of the trusses should meet at the panel points. But it is difficult to achieve as all the stress is exerted on members and connectors. Therefore, either the system lines should meet at one point or the system lines of diagonals should meet at least within the chord member in a roof truss. This is to manage the load and ensure proper functioning.

Hi, I’m Jim. I was a roofing constructor for 20 years, before deciding to start myrooff.com and gather the best content about roofing. I love woodworking and construction and it was only natural for me to start this passion project of mine. Thank you for visitng.